废旧塑料破碎清洗线

WASTE PLASTIC WASHING LINE

塑料是当今用途最为广泛的材料之一,每年全球产量接近4亿吨。提高塑料的循环再利用率,可以减少对塑料新原料的需求,从而可以:

1)节约原油;

2)减少生产新塑料的能耗;

3)减少填埋;

4)降低碳排放。

Plastic is one of the most popular and useful materials of modern times and it is important that we optimise the lifespan of plastics as much as possible. Worldwide we produce approx 400 million tonnes of plastic each year, re-using and recycling plastic as many times as possible can reduce our need to create new plastic , this means we can:

1)conserve non-renewable fossil fuels (oil);

2)reduce the consumption of energy used in the production of new plastic;

3)reduce the amount of solid waste going to landfill;

4)reduce emission of gases like carbon dioxide into the atmosphere.

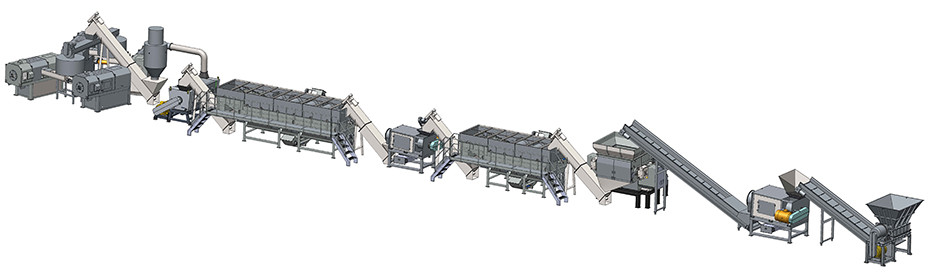

A、塑料薄膜破碎清洗线

PLASTIC FILM WASHING LINE

系统针对LDPE/LLDPE/HDPE/PP薄膜和PP编织袋、吨袋等,通过预碎、预洗、破碎、磨擦清洗、漂洗、脱水、干燥等工序去除物料表面泥沙、标签等杂质,使之成为可再生塑料。成套系统自动化程度高,产量大,运行稳定,安全可靠。处理产量1-2吨/小时。

The system can deal with LDPE/LLDPE/HDPE/PP film and PP woven bag, jumbo bag etc. Material will be processed by pre-shredding, pre-washing, crushing, friction washing, rinsing, centrifuging and drying, labels, dust and other contamination will be removed and finally you get dry, clean, recyclable plastic. The whole system is easy to operate, efficient and low power consumption. Capacity range from 1 to 2 ton per hour.

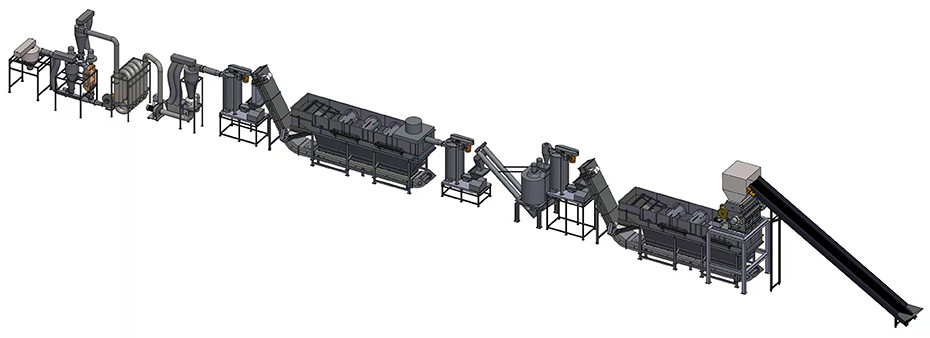

B、电器塑料破碎清洗线

WEEE PLASTIC WASHING LINE

系统针对电子电器塑料(机壳料),通常是ABS/PS/PC/PA/PP/PE等塑料混合料,通过预碎、磁选、破碎、漂洗、磨擦清洗、脱水、干燥及标签分选等工序,可将物料清洗干净并分选出PE/PP浮水混合物及ABS/PS/PC/PA等塑料,后续可根据用户需求进一步分选。成套系统自动化程度高,产量大,运行稳定,安全可靠。处理产量1-10吨/小时。

The system can deal with WEEE plastic, generally ABS/PS/PC/PA/PP/PE mixed rigid mixed plastic.Material will be processed by pre-shredding, magnetic separation,crushing, friction washing, rinsing, centrifuging, drying and labels separation. The whole system is easy to operate, efficient and low power consumption. Capacity range from 1 to 10 ton per hour.

C、日杂塑料破碎清洗线

HOUSEHOLD PLASTIC WASHING LINE

系统针对日杂塑料,通过预碎、磁选、破碎、漂洗、磨擦清洗、脱水、干燥及标签分选等工序,可将物料清洗干净并分选出PE/PP浮水混合物及沉水料,后续可根据用户需求进一步分选。成套系统自动化程度高,产量大,运行稳定,安全可靠。处理产量1-10吨/小时。

The system can deal with household plastic. Material will be processed by pre-shredding, magnetic separation,crushing, friction washing, rinsing, centrifuging, drying and labels separation. The whole system is easy to operate, efficient and low power consumption. Capacity range from 1 to 10 ton per hour.