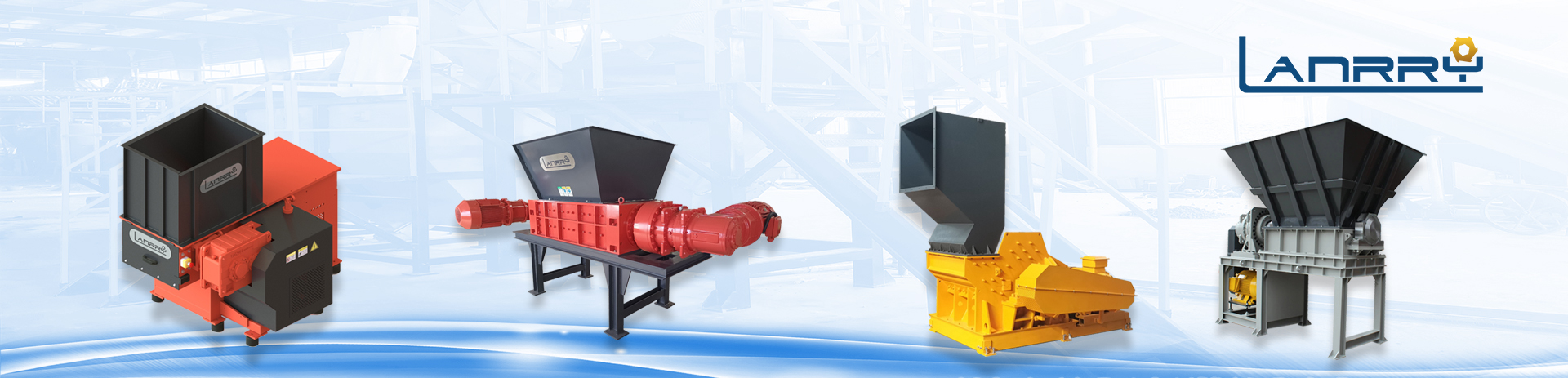

危废包装容器破碎清洗系统

HAZARDOUS WASTE CONTAINER RECYCLING SYSTEM

系统针对危废包装容器(HW49)进行无害化处理,使之成为可再生原料。按处理物料不同可分为以下两类:

The system is designed to deal with hazardous waste container (HW49), making them into renewable raw material. According to different material being processed, the system can be divided into the following two categories:

A、危废金属包装容器破碎清洗系统

HAZARDOUS WASTE METAL CONTAINER RECYCLING SYSTEM

系统针对危废金属包装容器(200L以下机油桶、油漆桶、机油滤芯等)采用物理处理工艺将物料通过撕碎、磁选、团粒、清洗、干燥等工序将物料表面残留物去除,回收高纯度可再生利用原料(非危险废物),成套系统自动化控制,安全可靠稳定,并可根据用户需求配置废气处理系统,成套系统符合环保要求。处理量1~5吨/小时。

The system can deal with hazardous waste metal container, material will be processed by shredding, magnet, crushing, washing and drying, hazardous residue and other contamination will be removed and finally you get dry, clean, renewable steel scraps. The whole system is easy to operate, efficient and low power consumption. Capacity range from 1 to 5 ton per hour.

B、危废塑料包装容器破碎清洗系统

HAZARDOUS WASTE PLASTIC CONTAINER RECYCLING SYSTEM

系统针对危废塑料包装容器(200L以下化工桶、油墨桶、机油壶、包装桶等)采用物料处理工艺将物料通过撕碎、预洗、破碎、高速磨擦清洗、漂洗、脱水、干燥等工序将物料表面附着物、残留物及标签去除,回收高纯度可再生利用原料(非危险废物),成套系统自动化控制,安全可靠稳定,并可根据用户需求配置废气处理系统,成套系统符合环保要求。

The system can deal with hazardous waste plastic container, Material will be processed by shredding, pre-washing, crushing, friction washing, rinsing, centrifuging and drying, hazardous residue,labels, and other contamination will be removed and finally you get dry, clean, recyclable plastic. The whole system is easy to operate, efficient and low power consumption. Capacity range from 1 to 4 ton per hour.